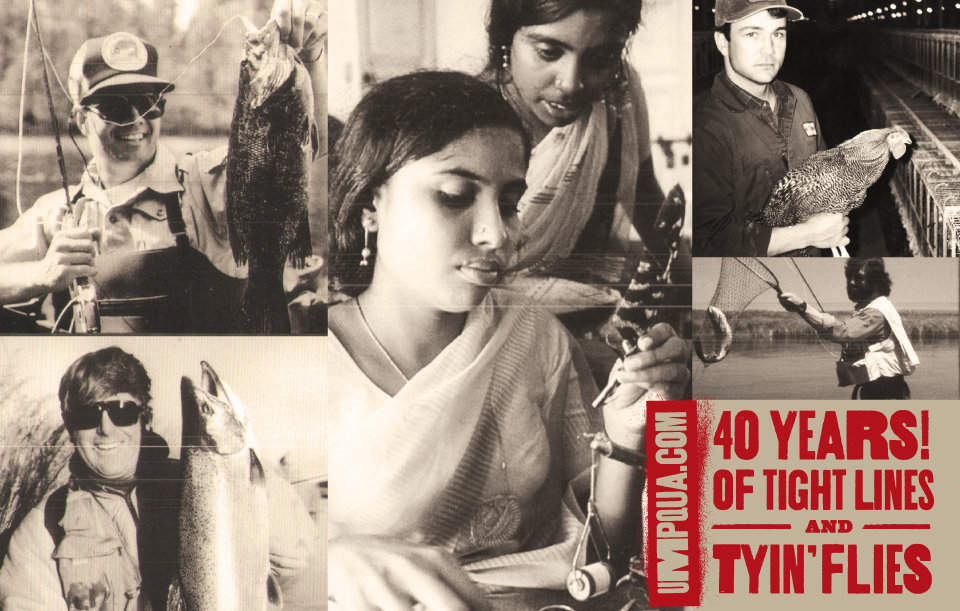

This exclusive interview with Jim Watson – Quality Control Manager for Umpqua Feather Merchants – was conducted by Howard Cole of High Country Flies. Jim’s wealth of knowledge gives us a historical perspective of the fly tying business that few possess. The interview details the evolution of one of the most influential companies in the sport of fly fishing and provides insight into a host of issues affecting anyone who has ever cast a fly.

In memoriam: In 2007, after a protracted illness, Jim Watson passed away. For all of us who knew and worked with him, we miss his humanity, his wit, his raw intelligence, and the sheer delight he felt when he skated dry flies to N. Umpqua steelhead

HCF: What year was Umpqua Feather Merchants established?

Watson: Dennis Black founded Umpqua Feather Merchants in 1972. Dennis had the core idea that high-quality fishing flies could be reliably tied in Asia as well as they could be tied here [in the United States]. From the 1950’s thru the 70’s, most fly shops sold flies tied by locals, both guides, shop owners, and from a number of commercial tiers. Getting large quantities of flies in a reliable manner was often a major problem. Dennis saw the need for better fly suppliers, and believed he knew the solution to the problem.

HCF: As Umpqua has come through a time of transition for the sport of fly fishing and is looked upon as a major player in the industry itself, can you reflect on some of the things Umpqua has done that has changed, not just the business of fly fishing but fly fishing in general?

Watson: I think Umpqua Feather Merchants has made us all better, more versatile fly anglers by greatly expanding our fly pattern horizons. Our fishing success certainly increased when Umpqua made available such an impressive array of patterns, once obtainable on a strictly local basis. And, perhaps most importantly, the quality of the newly available flies was dramatically improved. Increasingly, Umpqua made accessible—on a volume basis—fly patterns that were local favorites, but never got exposure beyond a fairly restricted area. Umpqua changed that limited availability to what over time became a national access to some of the most effective and newly designed patterns in the country.

Of almost equal importance was the use of Tiemco hooks in fly production, and the distribution of the hooks themselves. Many of us remember that the fist step in tying a fly on the hooks available years ago was sharpening the hook. You won’t find that step in most fly tying books today! The graceful, chemically sharpened Tiemco hooks, with their minute barbs and smooth finishes, made possible much more appealing flies—to the angler, at least. By its use of Tiemco hooks and Metz hackle, and by developing the consummate skills of its production fly tyers, Umpqua significantly raised the standards by which high-quality fishing flies were defined.

HCF: It wasn't so long ago flies tied outside the U.S. were frowned upon by shops and fisherman. I believe all Umpqua flies are tied outside the U.S. What made Umpqua think that they could get offshore flies accepted here in the United States? Also other companies had tried this approach unsuccessfully, what did Umpqua do differently?

Watson: Dennis Black knew that if he could manage to keep the quality of the flies very high, they would be accepted, eventually, in the U.S. In other words, the flies would sell themselves, if they were well tied and durable. Most of the resistance to foreign-tied flies had to do with the fact that their quality was so dismal.

Dennis noticed that arts & crafts produced in India, Sri Lanka, and Thailand, were often very detailed and of excellent quality. He reasoned that such craftspeople would make good fly tyers if supplied with the necessary tools, materials, and training. Probably the matter of greatest importance was setting the initial standards very high, and refusing to stray from those standards. And Dennis—as a commercial fly tyer himself—knew what was needed to make the operation work. He knew that the whole concept was doomed if anything but the highest quality materials were used. Initially, Dennis had to do a lot of training of the tyers himself. The manager of the Indian factory, for example, tied flies beside Dennis for an entire year to learn the patterns and the techniques. After a while, of course, the tyers gained enough skill and confidence to tackle any pattern proficiently. As much as any fly tyers on earth, the Umpqua Feather Merchants tyers know all the fundamentals of fly production. And, most importantly, they know the difference between a good, quality product, and a sub-par one. There are far more high-quality flies available now than ever before—and most of them are foreign-tied.

HCF: Even though your flies are tied outside the U.S., wasn't Umpqua one of the first companies to have their flies tied with domestic materials and high quality hooks? I don't know where all your materials come from but I do know that you use Tiemco Hooks and Metz Hackle. How important was this to Umpqua and could you explain a little on how this procedure works.

Watson: As mentioned earlier, the use of the very best materials was one of the most important developments in the history of Umpqua Feather Merchants, and was fundamental to its success. It was—and is—one of the very most important and difficult parts of the business. The change to Tiemco hooks was of particular importance. The dramatic superiority of Tiemco hooks allowed us to tie better flies. Over time, new hook models were developed which made possible increasingly interesting fly patterns.

Regarding hackle, low to medium grade feathers have always been available in Asia, of course, more so than in the United States. In fact, Dennis used to travel to India regularly in the 1960’s, sourcing and purchasing hackle for his fly tying business and to sell to American tyers. The feathers available in India were most appropriate for wet flies, streamers, and nymphs. Dry fly hackle was much harder to find. Dennis would often stay in India, traveling between Calcutta and Madras, high-grading any chicken pelts he could find, then bringing them back to Oregon. When Hoffmann and Metz began their operations, the constant problem of dry fly hackle availability became much more manageable.

Like most large fly manufacturers, we get our materials from every imaginable source. No business is safe from our appetite for materials. Fly tyers are masters at discovering creative uses for a bewildering array of materials. These materials are very rarely developed specifically for fly tying, of course. This results in an almost unbelievably broad selection of fly tying ingredients and presents all fly manufacturers with an equal number of headaches. Ask any fly producer in the world what their most persistent problem area is and they will all shout the same word: materials! Add to that the difficulty of keeping materials free from damage in tropical environments, and you have a real challenge. Material quality is a constant problem, as is dye-lot variation—so much so that I now consider ‘olive’ to be a general concept rather than a specific color. The variations are literally infinite. (I once had a well-known fly tyer describe a marabou color to me as, “A warm, milky, tannish-gray, with subtle, amber highlights.” Try ordering that color from your favorite fly shop!)

HCF: Because most of your factories are based in third world countries many people have commented to me, "that is why their flies are cheap," implying that Umpqua is taking advantage of the situation. Isn't it true that your offshore employees have superior wages, working conditions, and health benefits compared to the average citizen in these countries?

Watson: We go to great lengths to insure that the fly tyers at our factories are well paid, and work in an environment that is conducive to such an artistic enterprise. We comply thoroughly with the laws of the country in which the factory is located, and in all cases provide health care, and maternity leave (an important consideration when all the tyers are female). My observation has been that the tyers enjoy tying flies, and consider it a very good job. Obviously, they take a great deal of pride in their work. The tyers receive a base pay, and a bonus amount for exceeding production levels. Almost all of the tyers regularly earn the bonus as well as the base pay. For these reasons, among others, there is a very low turnover rate among our fly tyers.

The Umpqua fly tying facilities are very comfortable and pleasant, and they are all air conditioned—an important consideration in climates that can be very hot. As mentioned earlier, much emphasis is placed on creating an environment conducive to comfort and creativity. Considering the often overwhelming demands we place on the factories, it just would not work any other way.

HCF: Umpqua has contract fly tyers to whom they pay royalties for patterns that they have developed while many other companies don't. Again, you were one of the first companies to institute this kind of a program. I have seen two things come from this. One is that it has made celebrities out of some of these fly tyers. Two is that in the old days you would have many specialty patterns only known locally, now they are universally known. Can you give us a little insight of why Umpqua went with a program like this and how important do they feel it is to keeping them on the cutting edge of new patterns?

Watson: As a commercial fly tyer himself, Dennis considered it essential to reward tyers for their creativity. At the time, I think he was interested in helping the tyers make a living from fly tying—so as to free up more time to create and refine new patterns—and insure that Umpqua had a reliable supply of well designed, thoroughly tested fly patterns. At one time, at least, most of the best fly tyers in the Untied States were associated with Umpqua Feather Merchants. Keep in mind that twenty or thirty years ago there were a limited number of ‘master fly tyers’ in the country. That’s not true any more, and today there are easily thousands of gifted fly tyers in the United States and throughout the world.

In the beginning, as now, only the very best fly designers were chosen as Umpqua royalty tyers. People like Mike Lawson and A.K. Best, who exhaustively tested every fly pattern they developed. The basic idea was pretty simple, really: reward financially the tyers who gave their patterns exclusively to Umpqua. It was a real benefit to offer the select patterns of Dave Whitlock, Mike Lawson, or Randall Kaufmann, to fly shops all over the country. The influence and importance of the royalty tyer program cannot be overstated. It was (and is) the royalty tyers’ constant attention to detail that helped us achieve our reputation for tying the best flies available.

HCF: Many companies compare themselves to Umpqua for price, quality, delivery, and service. What are some of the things Umpqua does to stay ahead?

Watson: Each and every year, we introduce approximately 100 new fly patterns. (We get roughly 600 new fly submissions annually, and it can be a difficult matter to choose those that will be popular with the fish—and the angler—without exceeding production capacity.) After all, that’s what we’re all looking for: new and original fly patterns that the fish haven’t seen before; flies that give the angler just a little more confidence, and at least a perceived advantage. We spend a lot of time and effort maintaining the quality standards that made Umpqua the world’s largest fly manufacturer. We try hard to avoid complacency, because after a while the temptation is to produce flies that are “good enough” as opposed to “excellent.” We constantly strive to make our operations not only more efficient, but more quality and customer conscious.

HCF: How has the industry changed since Umpqua's first beginnings?

Watson: Oh boy, you could write a book on that subject! Fly fishing has changed dramatically in the last thirty years, of course, and fishing flies have certainly not been unaffected. The ‘synthetics revolution’ has changed forever the face of fly tying and fly-fishing. Every aspect of our sport has changed radically, from the rods, reels and lines we use to cast the flies, to the clothing we wear while we’re fishing.

In 1972, there was little in the way of competition in the world of production fishing flies. If you produced some basic nymphs, some streamers, and a selection of Catskill dry flies, you had just about everything any fly shop wanted. Today, fly shops have become much more versatile and resourceful, and the people working in them much more knowledgeable. If you had walked into a shop in Montana in 1972 and asked a question about bonefishing, you probably wouldn’t have received much in the way of useful information. Now you can learn a great deal about conditions in just about any fishable water in the world, make all the arrangements for an exotic trip, and probably purchase the gear you need all in the same fly shop. These days, you are about as likely to find a tarpon expert in Colorado as in Florida!

In recent years, competition has intensified significantly among fly fishing manufacturers. The result has been not only better flies and availability, but also outstanding quality in everything we use, from fly tying vises to clothing. Who would give up their Gore-tex waders, or their premium high modulus graphite fly rod for the gear of yesterday? Umpqua Feather Merchants has had a seminal and historic role in the growth of fly fishing, and in the appreciation of the importance of high quality products…especially fishing flies.

HCF: After all these years what would you say are some of the major factors that have contributed to putting Umpqua where they are today?

Watson: First and foremost, the high quality of the product. We are fortunate to have many exceptionally gifted fly tyers in our factories, and of course, among our royalty tyers. The dedication of our tyers in Asia has been vitally important to our success. Of particular significance is the involvement of the fly designers themselves in the production process. Next to that, actually being able to deliver the flies, on time, has been of utmost importance, and it is something we have done very well for a very long time. Our Customer Service department is conscientious and capable and continually trying to improve itself. The Umpqua Sales Reps are a remarkably talented and knowledgeable group who are never satisfied with the status quo. They have done a very good job of making our products available to most of the country, and their goals have always remained high. But, once again, the most important matter of all has been the outstanding quality of the flies themselves. That, more than any other attribute, is what made Umpqua Feather Merchants the company it is today.

HCF: And now for the question that everybody wants to know. How many different patterns does Umpqua have?

Watson: If you count separate colors as separate flies, the number of production and special patterns is approximately 2,000. That may vary a little year to year, but there are rarely fewer than about 1,800. (In 2011, Umpqua offers close to 2,649 fly/colors, totaling over 6,000 total fly sizes)

Obviously, some of Umpqua’s flies are much ‘prettier’ and more complicated than they need to be to simply catch fish. But I think such flies satisfy a need in most fly anglers and fly tyers. I remember when I was a kid in Colorado, spending the winters filling my fly boxes with little gems of fur and feather. Each opening day I would almost reluctantly remove a fly from the carefully ordered rows. They were, after all, boxes full of delightful jewels, carefully designed and organized as much to satisfy some sense of beauty in me as to catch fish. Each fly promised a whole world of exciting possibilities. And, after all, that’s what fly fishing is about: creating, having, and holding the key to so much excitement and wonder. In every fly angler I think you’ll find a deep appreciation for the modest works of art we call fishing flies. We at Umpqua Feather Merchants do our best to insure that every fly angler has just the right fly for every imaginable situation.